Precision sheet metal fabrication is one of the most effective and versatile manufacturing processes. It helps you create complex shapes and custom designs that maintain their durability and strength while also being relatively lightweight. This method is commonly employed in a wide variety of industries, including medical, industrial equipment, electronics, printing, automotive, aerospace, agriculture, and others. In this article, we’ll cover the benefits of metal fabrication in each of these industries.

Medical sheet metal fabrication

Medical sheet metal fabrication has a huge number of applications. It is used in multiple facets of the industry to manufacture everything from enclosures for diagnostic equipment and surgical components, to carts, bed frames, ventilation components, workstations, and more. The advantages of medical sheet metal fabrication are:

- Precise manufacturing – Surgical tools and equipment require tight, accurate tolerances.

- Cleanliness – Stainless steel and antimicrobial finishes are perfect for sterile environments.

- Lightweight and durable – Sheet metal fabrication delivers the best balance between portability and structural strength.

Industrial equipment sheet metal fabrication

Industrial equipment sheet metal fabrication is utilized to manufacture machine housings and enclosures, conveyor system components, structural supports, and many other parts and products. There are numerous benefits of using precision sheet metal fabrication for industrial equipment, but here are the top three:

- Durability – Sheet metal fabrication provides products that are exceptionally strong, perfect for harsh industrial environments.

- Scalability – Fabrication allows you to move from prototypes and small runs to high volume production very quickly, because of repeatability, flexible processes, and automation.

- Compatibility – When completed by an experienced sheet metal fabricator, like Highland Machine, this manufacturing method provides extremely tight tolerances, which is necessary for all industrial equipment.

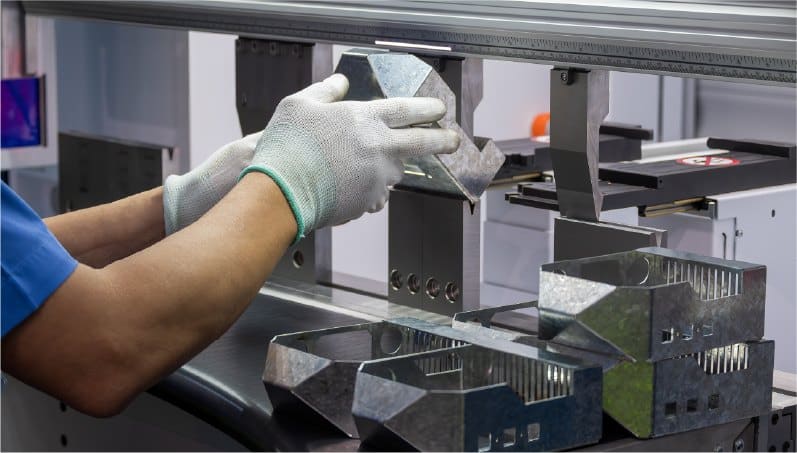

Electronics sheet metal fabrication

Many electronics are compact and have to be relatively lightweight. Electronic sheet metal fabrication checks both of these boxes and is used to manufacture a host of different products and components, including sheet metal enclosures and cabinets to hold sensitive components, racks and mounting plates, shielding, fan and duct components, and much more. Its primary advantages are:

- The ability to customize components and enclosures – Sheet metal can be fabricated into extremely thin and lightweight parts, perfect for fitting into small spaces within electronic devices. It can also be easily cut to allow for ventilation and wiring access.

- Versatility – This method can be used with a variety of different metals, aluminum for lightweight requirements and steel for strength.

- EMI shielding – Sheet metal enclosures can be designed to provide electromagnetic interference (EMI) to protect sensitive components.

- A wide range of compatible coatings – Special coatings and finishes can be added to insulate the sheet metal component or increase conductivity.

Printing industry sheet metal fabrication

This method is widely used in the printing industry to manufacture everything from paper guiders and feeders, to machine enclosures, press frames, and ink trays and application systems. The top reasons that manufacturers use sheet metal fabrication in printing are:

- Component strength – Sheet metal fabrication creates parts that can withstand heat, friction, and ink exposure.

- Tight tolerances – This type of manufacturing produces products to exact specifications, which is necessary for accurate printing, paper feeding, and alignment.

Automotive and aerospace sheet metal fabrication

Automotive sheet metal fabrication and aerospace sheet metal fabrication is used throughout almost every stage of vehicle or aircraft manufacturing. It is an efficient, repeatable process that is used to produce body components, like doors, hoods, fenders, and roofs, chassis and frame parts, wings, flaps, brackets, custom panels, engine components, and much more. The advantages of automotive and aerospace sheet metal fabrication are:

- Cost effectiveness – Precision sheet metal fabrication enables manufacturers to produce large volumes of components using automation and economies of scale to bring down costs.

- Lightweight and corrosion resistant – Many types of steel and aluminum resist wear and corrosion or can be coated to increase their durability. They are also strong without being too heavy, perfect for reducing vehicle and aircraft weight.

- Complexity – Techniques like bending, punching, and drawing can provide customized, intricate shapes.

Agricultural sheet metal fabrication

Precision sheet metal fabrication is used in agriculture to manufacture silos, grain bins, and other storage structures, farm equipment components, parts for irrigation systems, animal housings, tools, and more. Its primary benefits in the industry are:

- Weather, water, and chemical resistance – Stainless steel and powder coating finishes help components take on the harsh environments found in the agricultural industry.

- High strength without being too heavy – Similar to many other industries, agriculture requires components that deliver durability while remaining relatively lightweight.

- Easy integration – This method provides custom parts that fit seamlessly within existing structures or pieces of equipment.

Precision fabrication for OEM parts manufacturers

OEM parts manufacturers often rely on sheet metal fabrication to produce components for all the industries we’ve talked about. The benefits are the same as in those industries: customization, durability, tight tolerances, repeatability, scalability, and the ability to manufacture complex shapes.

Why work with Highland Machine

At Highland Machine, we are more than just another sheet metal fabricator. We’re successful in all of these industries because we offer a wide range of services in house. Our team handles sheet metal fabrication, precision machining, custom finishing, and assembly. You have one vendor and one point of contact, simplifying your production process and bringing down costs compared to using multiple vendors. If you’re in one of these industries and looking for a fabricator or precision machine shop, contact us for a quote today!