Consolidate Your Vendors: We Offer Sheet Metal Assembly Services

For many of the businesses we work with, one of their biggest challenges is the need to coordinate, communicate with, and stay on top of multiple vendors. Most often, each stage of their project is completed by a different provider. The problem with this type of model is that it takes a lot more time and effort on the part of our customers and makes the entire process more difficult and longer than would be required with one company handling everything.

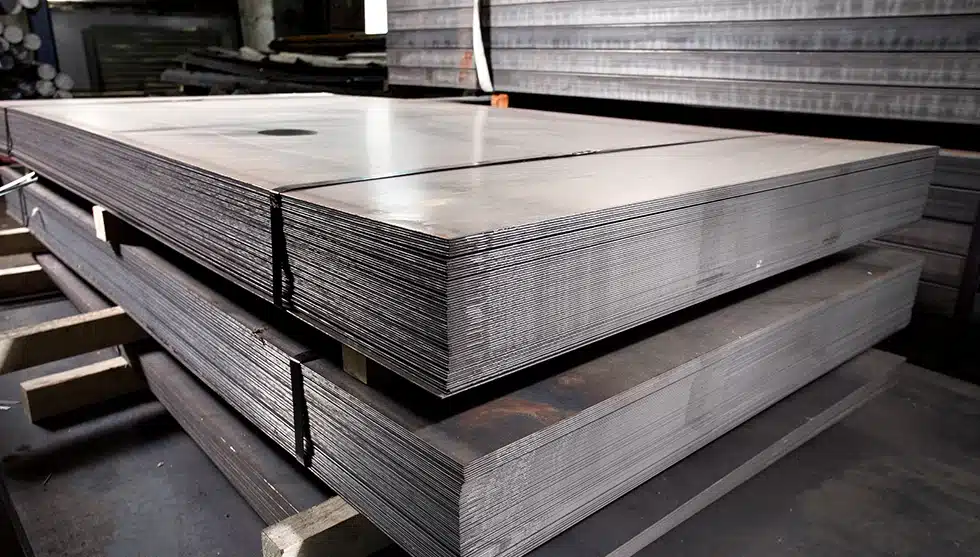

At Highland Machine, we’re an end-to-end sheet metal fabricator that provides all the services needed for the entire project in house, so you can work with a single vendor and reduce project time and costs. Our team completes everything, from the fabrication or machining, to the finishes, powder coating, and, finally, the sheet metal assembly.

Sheet metal assembly: A value added service

After manufacturing and finishing the various components of your product, the final stage is actually putting them together. Sheet metal assembly can involve different methods, such as welding, adhesives, rivets, or threaded fasteners and other types of hardware. There’s no one-size-fits-all solution when it comes to sheet metal assemblies, and the methods used will depend on the function of your final product, the materials the individual components are made of, and the shape and size of the separate parts.

At Highland Machine, we provide the following sheet metal assembly options:

- Mechanical assembly – This method uses various hardware or fasteners to join and assemble multiple parts.

- Electrical assembly – This option involves constructing pieces of equipment that control electrical current. We precisely fabricate and assemble sheet metal parts to house electrical components.

- Electronic enclosure assembly – We assemble custom electronic enclosures using mechanical, spot welding, and other methods.

How long do sheet metal assemblies take?

The amount of time needed for sheet metal assembly varies from project to project. The number of components your final product includes, the complexity of the different parts, the specific assembly method, how big the final product will be, and a variety of other factors all play a role in how long this stage of the process takes.

When you work with us, our team will keep you fully informed and updated about how long each step of your project takes and whether any delays are encountered during the process.

Highland Machine is your one stop shop for fabrication, sheet metal assemblies, and more

By providing sheet metal assembly as a value added service, we give you a ready to ship product, completely developed under one roof. The majority of manufacturers and metal fabricators do not handle the assembly stage of the project, forcing you to find a separate vendor, which can cause delays. By relying on our team, you only work with one provider, and you can be sure your product will be assembled with the same quality and attention to detail that the components were manufactured with.

If you want a fully manufactured and assembled product, contact our team and tell us about the job today!